TRUSTED SOLUTIONS FOR WAREHOUSE CONVEYOR SYSTEMS

As a conveyor system integrator, RMH Systems helps companies move product quickly with distribution center conveyor systems and warehouse conveyor systems so they can fulfill orders faster. We’ve implemented thousands of material handling conveyor systems across the country, including ones for individual products, case conveyors and pallet conveyors. Although we’re not a conveyor manufacturer, we can design the right conveyor systems for your needs. If you don’t see exactly what you’re looking for, RMH can engineer a custom system exactly to your specifications.

Live Roller Conveyors

Powered rollers move boxed and palletized products. Great fit for manufacturing, distribution and warehouses.

Belt-Over Roller Conveyors

Conveyor with belts over roller/slider beds. Provides better support, more precision, and stronger grip.

Chain Conveyors

Designed for pallets or heavy loads. Powered chains support the conveyed load. Economical, durable pallet handling.

Gravity Conveyors

Non-powered conveyor. Very economical, versatile solution to convey product. Good for shipping and assembly areas.

Zero Pressure Conveyors

Product does not touch on the line while accumulating. Great for distribution or sorting lines. Minimum pressure available too.

24-Volt Conveyors

Only requiring 24 volts, this accumulation conveyor is powered by a decentralized drive system. Applications include manufacturing, food and beverage, warehousing, etc.

CDLR Conveyors

Heavy-duty conveyor used to transport pallets. Driven by a chain for power, and can be integrated with transfers. Good for heavy product in dirty environments.

Sortation Conveyors

Many sortation options including shoe, narrow belt, ARB and pivot wheel. Sort at rates up to 120 per minute.

Food Grade Conveyors

Designed to improve food safety. High-quality stainless steel conveyors are washdown ready and easy to clean. FDA certified.

Low Profile Conveyors

High-performance, low profile conveyor perfect for small product handling, transfers and precision parts movement. Many options available, including roller, pallet, belt, chain, chip and drag.

Plastic Modular Belt Conveyors

Plastic belt conveyor systems can convey a variety of product. Perfect for packaging, manufacturing, food and beverage or pharmaceutical.

Line Shaft Conveyors

Designed with a driveshaft that provides power to the rollers. Economical transport conveyor option.

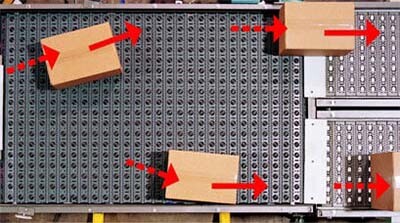

Activated Roller Belt Conveyors

Designed for ultimate product manipulation. Sort, align, singulate, transfer or sort cases with minimal contact.

Vertical Conveyors

Options for continuous or vertical reciprocating conveyors. Move product to multiple levels to convey product on a mezzanine or over obstructions.

Power and Free Conveyors

Monorail conveying systems that transfer parts through an assembly operation. Provide ability to stop specific parts without stopping line. Many options available, including overhead, overhead trolley, roller and chain.

Spiral Conveyors

Convey product to multiple levels with spirals. Save floor space and money. Belt-over, live roller, and modular belt options.

CONTACT US

Fill out the form below to get in touch with our engineers.

Contact RMH Systems

"*" indicates required fields